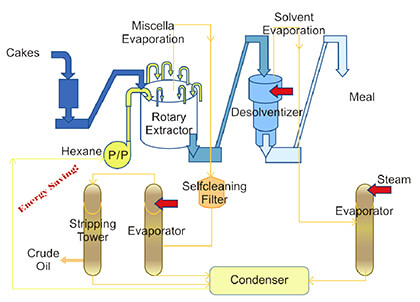

Solvent Extraction Process

Solvent extraction process is according to the extraction principle, choose the organic solvent which can dissolved in oil, after contact with oil (soaking or spraying), finally obtain oil from the oil materials. Our company is committed to the solvent extraction plant, according to your needs, to provide solvent extraction system capacity ranges from 300kg to 100MT. The oil grade after refined can reach to Grade 1, Grade 2, Grade 3, and Grade 4 Oil etc.

Solvent Extraction Plant

Basic Process Of Solvent Extraction Plant

The oil embryo (or pre pressed cake) is immersed in the selected solvent, the oil is dissolved in the solvent (composed of mixed oil), and then the mixed oil is separated from the solid residue. The mixed oil is evaporated and lifted according to different boiling points, so that the solvent is vaporized to be separated from the oil by steam, and thus, the oil is obtained (leaching crude oil). Solvent vapor is condensed, cooled and recycled. There is a certain amount of solvent in the meal, which is dried by the drying process, and the solvent vapor which is produced in the process of dehydration and drying can be recovered by condensation and cooling.

Advantages Of The Solvent Extraction Process

- The solvent extraction system residual oil rate is low (the oil yield is high). Residual oil below 1%.

- Low labor intensity, easy to automate production. Good working environment, no leakage, no dust, low production temperature.

- The quality of the meal is good, and the protein denaturation degree can be obtained to be used for the extraction and utilization of the oil protein. The utility model is convenient to improve the nutrition and the use value of the feed, and is convenient for improving the efficiency of the fertilizer.

How Many Kinds Of Oil Producing Technology Are There In The Solvent Extraction Process?

- Direct extraction: direct extraction is also called once-extract. It is a process of directly preparing oil by pretreatment of oil. This process is suitable for processing low oil content oil.

- Prepressing extraction: prepressing extraction is the oil by pre-pressing part of oil, then take extraction process with the high oil cake. The process is suitable for the oil with high oil content.

How To Choose The Right Solvent Extraction System?

① According to the variety and nature of raw materials to choose. According to different varieties of raw materials, using a different process and oil mill machinery.Cottonseed:

- Cottonseed → cleaning →delinting → shelling →separation of hull and kernel → softening →flaking → steaming → pre-pressing → extracting

- Rapeseed →cleaning →flaking → steaming → pre-pressing →extracting

- Soybean → cleaning → crushing → softening →flaking → drying → extracting

- Soybean → cleaning →drying → heat treatment →crushing → peeling → softening →flaking →extracting →extracting meal → baking → cooling → crushing → High Protein Soybean Powder

Wet Meal Desolventizer The wet meal desolventizer is suitable for the wet meal from vegetable oil, which take by a solvent extraction process. The desolventizer comprises a solution, a solution, a drying and cooling device. The desolventize...

Solvent Evaporation Equipment Solvent evaporator is a very important solvent evaporation equipment in the solvent extraction process. The evaporation of mixed oil is characterized by the fact that the oil is not volatile, and the boiling po...

Oil Seed Extractor The oil seed extractor is the main equipment in the solvent extraction process. There are a variety of main equipments such as rotary extractor and loop type extractor. Rotary Extractor The rotary extractor is a kind of o...