Meat Duck Cage System

Customer Satisfaction: ★★★★★

Cumulative Sales: 110,000 Sets

Application:meat duck

Type: H-Type duck cage

Tiers: H-Type: 3 Tiers

Certification: SONCAP, PVOC, OHSAS18001, CE

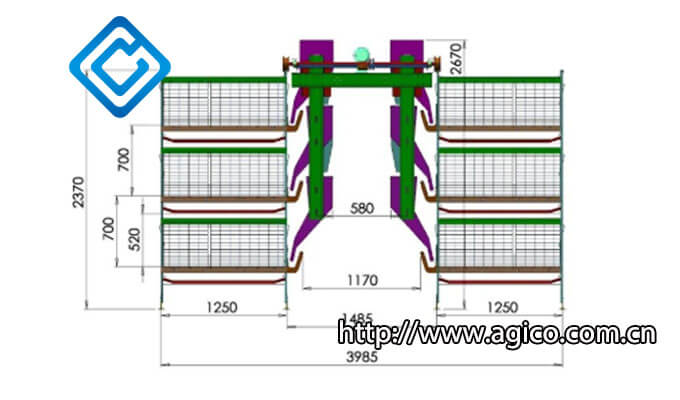

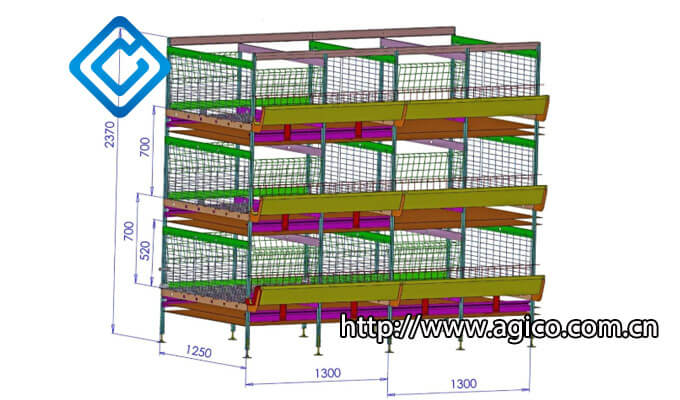

Size(mm): H-Type: 1300×1250×2370

Duck Cages for Sale

With the continuous development of the poultry industry, large-scale poultry breeding has entered the era of cage breeding. The various poultry breeding cages launched by AGICO conform to the needs of the times and help 100,000+ customers around the world realize the automatic breeding of meat ducks.

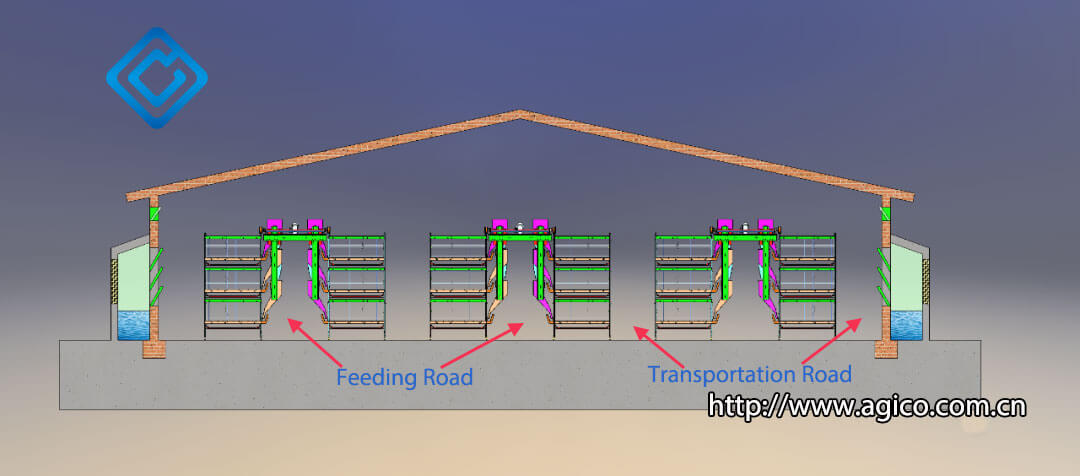

The AGICO meat duck cage system adopts stacked cages for breeding, which not only has a large scale of breeding but also is easy to automate management. This automated indoor duck cage will become the main breeding trend for duck farming. The indoor duck cage system effectively solves the problems of drinking water, feeding, and feces cleaning during the breeding process, making meat duck breeding more automated.

AGICO New Designed Meat Duck Cages

The newly upgraded AGICO H-type meat duck cage has abandoned the shortcomings of the old-fashioned duck cage indoor, such as the small door and the poor ventilation effect of the back-to-back layout. space, reducing the damage to the meat duck.

Our indoor duck cage adopts the layout pattern of leaving channels on both sides of the cage frame, which greatly improves the ventilation of the entire duck house, facilitates the transportation of meat ducks out of cages, and effectively reduces the outbreak rate of meat duck epidemics.

Old-fashioned meat duck cages indoor

- The small cage door design of the meat duck cage indoors makes the grabbing efficiency of the meat duck low, and it is easy to cause the meat duck's wings and leg bones to be fractured and injured.

- The small cage door design makes it inconvenient to observe the growth status of meat ducks during the breeding process.

- Duck breeding cages are placed back-to-back in the duck house, resulting in poor ventilation effect of the whole duck house and easy to cause epidemic.

New designed meat duck cage

- The larger rear cage door design makes it more convenient for meat ducks to come out of the indoor duck cage and reduces the disability rate of meat ducks.

- One side of the duck cage door is designed with a meat duck transportation channel, which is more convenient for duck transportation and management.

- The interval between indoor duck cages is increased, which solves the problem of poor ventilation quality under high-density meat duck breeding.

Duck Cages Indoor Design and Specifications

| Dimension(mm)/set | Tier | Door/tier | Area/duck | Bird/door | Bird/set |

|---|---|---|---|---|---|

| 1300×1250×2370 | 3 | 1 | 625cm2 | 26 | 78 |

AGICO indoor duck cage is suitable for every stage of meat duck growth

The three growth stages of meat ducks are young ducks (1-9 days old), middle ducks (9-26 days old), and big ducks (26-40 days old). Due to the constant changes in body weight of meat ducks in different growth stages, it is necessary to adjust the height of the drinking device and the stocking density in a timely manner. AGICO indoor duck cage system, drinking fountains, feeding troughs, and other devices can be flexibly adjusted in height.

Since the feeding density of middle ducks is about 20-25 ducks / m2 and that of big ducks is about 14-19 ducks / m2, it is very necessary to design the cage door for easy access during the feeding of meat ducks. The indoor duck cage recommended by AGICO for you is designed with a large cage door and a transportation channel on one side of the cage door, which is more convenient for the transportation of meat ducks.