Chicken Layer Cage System

Customer Satisfaction: ★★★★★

Cumulative Sales: 300,000 Sets

Application: laying hens

Type: A-Type layer cage, H-Type layer cage

Tiers: A-Type(3-4 Tiers) , H-Type(3-6 Tiers or duplex multilayer 4+4 and 3+3+3 Tiers)

Certification: CE, ISO9001, SONCAP, PVOC, OHSAS18001

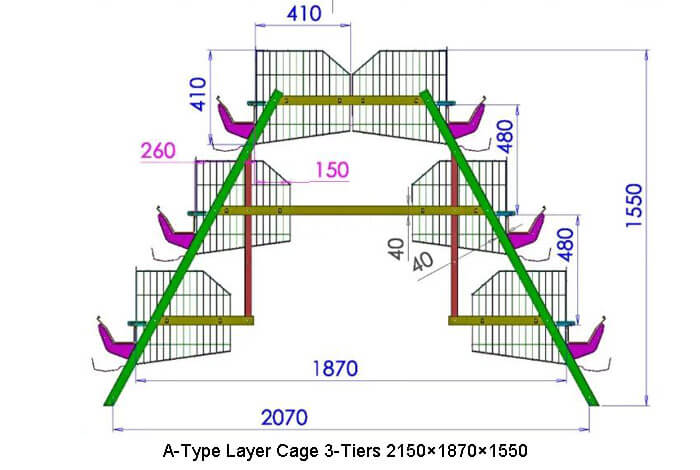

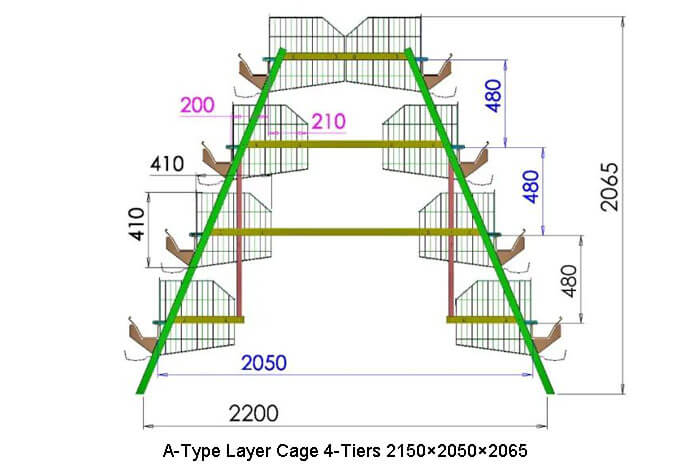

Size(mm): A-Type: 3-tiers 2150×1870×1550, 4-tiers 2150×2050×2065

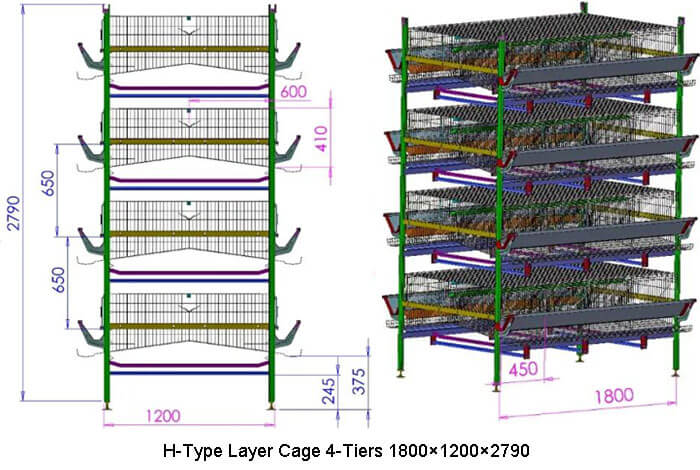

H-Type: 3-tiers 1800×1200×2140, 4-tiers 1800×1200×2790

Chicken Layer Cages for Sale

For caged laying hen farming, generally after the chicks grow to 15~18 weeks, they are moved from the chick brooding cage to the chicken layer cage to continue breeding. Laying hens are kept in layer cages until about 72 weeks old, and will not be eliminated until the egg-laying cycle is completed. Therefore, in addition to having a good chicken house environment, it is also necessary to have a well-structured chicken layer cage, so that the laying hens can exert their highest production efficiency.

The new high-precision layer cage launched by AGICO Group adopts a fully assembled installation method, which is easy to install and easy to maintain. The chicken layer cage is made of integral hot-dip galvanized material, with a service life of 20+ years. In line with the vision of providing a more comfortable environment for laying hens, FamTech has designed a more reasonable chicken cage structure to improve the egg production quality of laying hens and bring greater economic benefits to chicken breeding enterprises.

The intensively designed layer cage system, with advanced automatic feeding, drinking water, manure cleaning, egg collection, and air quality control systems, fully saves energy consumption and improves labor productivity. Focusing on the production needs of modern laying hens, FamTech can provide the design and manufacture of A-type chicken cages, H-type chicken cage equipment, and layer cage house breeding systems according to the planning and service life of the customer chicken farm.

A-Type Layer Cage Design and Specifications

| Dimension(mm)/set | Tier | Door/tier | Bird/door | Bird/set |

|---|---|---|---|---|

| 2150×1870×1550 | 3 | 10 | 4 | 120 |

| Dimension(mm)/set | Tier | Door/tier | Bird/door | Bird/set |

|---|---|---|---|---|

| 2150×2050×2065 | 4 | 10 | 4 | 160 |

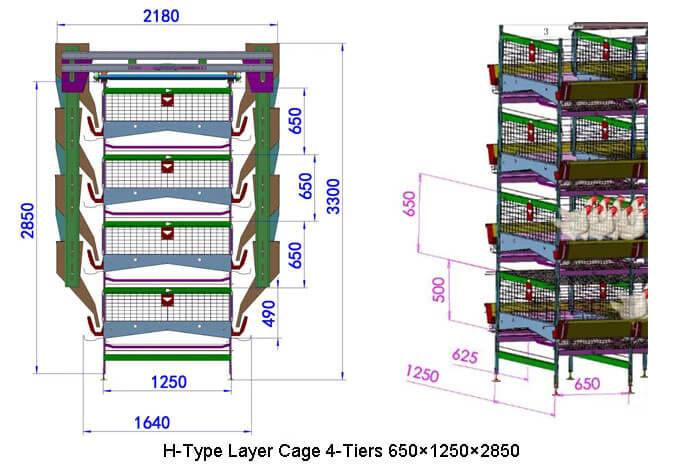

H-Type Layer Cage Design and Specifications

| Dimension(mm)/set | Tier | Door/tier | Bird/door | Bird/set |

|---|---|---|---|---|

| 1800×1200×2140 | 3 | 8 | 6 | 144 |

| 1800×1200×2790 | 4 | 8 | 6 | 192 |

| 1800×1200×3440 | 5 | 8 | 6 | 240 |

| Dimension(mm)/set | Tier | Door/tier | Bird/door | Bird/set |

|---|---|---|---|---|

| 650×1250×2200 | 3 | 2 | 9 | 54 |

| 650×1250×2850 | 4 | 2 | 9 | 72 |

| 650×1250×3500 | 5 | 2 | 9 | 90 |

| 650×1250×4150 | 6 | 2 | 9 | 108 |

| 650×1250×2850 |

Duplex multilayer 4+4 |

2 | 9 | 144 |

| 650×1250×2200 |

Duplex multilayer 3+3+3 |

2 | 9 | 162 |

Unique Features of Chicken Layer Cage

- The overall frame of the layer cage is positioned and processed with high-precision technology, assembled and formed with stainless steel screws, with reasonable design, not easy to deform, and durable.

- The bottom net of the chicken layer hen cage is made of wire with high toughness, which will slowly rebound after deformation, effectively protecting the eggs and reducing broken eggs and dark-grained eggs. The chicken layer cage is equipped with an egg buffering device. When the eggs roll down rapidly, the buffering device will effectively hinder the eggs, so that the eggs can fall smoothly on the egg conveyor belt and reduce the egg breaking rate.

- The chicken layer cage adopts a fully open cage door design. The cage door is convenient to open and close, and the feeding position of the laying hens can also be adjusted as needed.