Manual vs. Full Automated Incubators: How to Choose the Best Fit for Your Farm

In poultry farming, the poultry egg incubator is a vital piece of equipment. Whether small-family breeding or large-scale commercial breeding, egg incubators can significantly improve hatching efficiency and success rate. In-home breeding, egg incubators provide farmers the convenience of hatching healthy chicks while controlling environmental conditions. In commercial farms, egg incubators are even more indispensable. They can hatch a large number of poultry in a short time to meet market demand and improve production efficiency. Therefore, egg incubators simplify the incubation process and help farmers achieve high yields and profits.

Buy Incubator for Hatching Eggs

However, choosing a suitable poultry incubator is not an easy task, especially when faced with the choice between manual incubators and full automatic incubators. Different farming scales and needs often require different types of incubation equipment. For smaller farmers, manual incubators may be more economical, but they require more manual intervention. For large-scale farms, although automatic egg incubators are more expensive, they can reduce labor costs and improve hatching efficiency through automated management systems. Therefore, farmers need to make a trade-off between the type, cost, function, and farming goals of the incubator to choose the incubator that best suits their needs.

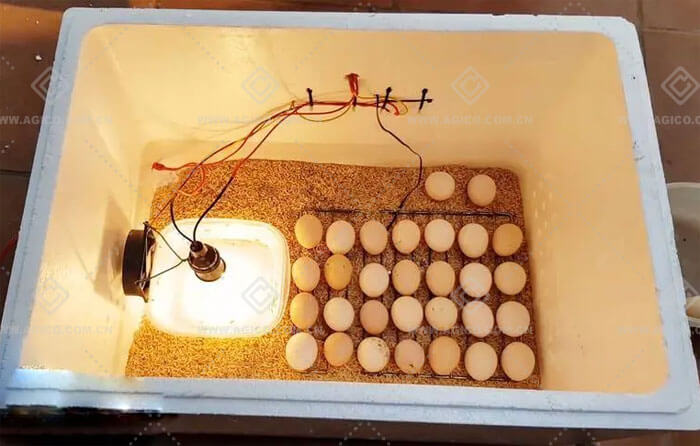

Manual incubator

A manual incubator is a traditional incubation device that relies on the farmer to manually control and manage various key factors in the incubation process, such as temperature, humidity, and egg turning frequency. This type of incubator usually does not have an automated adjustment function, so users need to use their own experience and judgment to control the incubation conditions. The design of a manual incubator is relatively simple, usually consisting of a heating element, a humidity control device, and a manual egg-turning device. Although this device has a low technical content, it can provide farmers with a certain degree of operational freedom, allowing them to participate in and control the incubation process more directly.

Advantages

-

Lower cost

Manual incubators are relatively inexpensive and are ideal for farmers with limited budgets. Especially for small family farmers, manual incubators can provide basic incubation functions with less initial investment. -

Simple operation

The operation of manual incubators is not complicated, and even users without much technical background can easily get started. Just follow the simple instructions and farmers can start the incubation process without complex technical knowledge or high-tech equipment. -

Higher freedom of control

Since manual incubators require farmers to personally control the incubation conditions, this equipment provides more flexibility for experienced farmers. They can adjust the temperature, humidity and egg turning frequency at any time according to actual conditions and personal experience, which may better meet the incubation needs of specific egg types.

Disadvantages

-

Reliance on manual operations

One of the main disadvantages of manual egg incubators is their high reliance on manual operation. Farmers must frequently manually adjust the temperature and humidity and turn eggs regularly, which may cause inconvenience in daily life, especially when the hatching volume is large. -

Lower hatching success rate

Manual operation may cause human errors, such as temperature fluctuations, unstable humidity, or failure to turn eggs in time, resulting in unsatisfactory hatching conditions and thus affecting the hatching success rate. This risk always exists during incubation and requires farmers to pay close attention and meticulous operation. -

Time consuming and labor intensive

Using a manual egg incubator requires a lot of time and effort, especially when the hatching volume is large, the difficulty and workload of management and operation will increase significantly.

Automatic Egg Incubator for Sale

A full automatic incubator is a modern incubation device that automatically regulates key parameters of the incubation process, such as temperature, humidity, and egg turning frequency, through built-in intelligent systems and sensors. Automatic egg incubators are usually equipped with a digital display and control panel that allows the user to set and monitor incubation conditions, while the device maintains the stability of these parameters throughout the incubation process. Such equipment also usually includes an alarm system that prompts the user to check and intervene when anomalies are detected. Automatic incubators are designed to minimize the need for manual operation, making the incubation process more efficient and reliable.

Advantage

-

Reduce manual operations

Full automatic egg incubators greatly reduce the need for manual intervention. Once the incubation conditions are set, the device automatically manages temperature, humidity, and egg turning. This automation reduces the possibility of human error, making operations easier while giving farmers more time to handle other tasks. -

High hatching success rate

Since full automatic incubators can maintain constant incubation conditions and avoid the problems of temperature fluctuations and unstable humidity, the hatching success rate is usually higher. This is especially important for high-volume incubations, as it can significantly increase overall yield and reduce losses. -

Save time and effort

The automatic egg incubator automatically completes many tedious tasks during the incubation process, such as regularly turning eggs and adjusting humidity, thus saving farmers time and energy. This savings is especially noticeable for larger farms, making the hatching process more efficient.

Disadvantages

-

Higher cost

Automatic incubators are usually more expensive, and the initial investment cost is significantly higher than that of manual incubators. This may be a burden for small farmers with limited budgets, especially when upgrading equipment or expanding. -

Technical complexity

While automatic incubators are easy to operate, their technical complexity can also cause problems. Equipment failure or system errors may cause hatching failures, and professional technicians are required for repair and maintenance. -

Maintenance and repair costs

The complex structure and advanced technology of automatic incubators mean that maintenance and repair costs may be high. Once the equipment fails, the repair costs and time investment may affect the hatching cycle and thus affect production plans.

Selecting an Incubator Based on the Size of Farm

Small-scale family farms

- Recommended options: manual incubators or automatic egg incubators.

- Reasons: For small-scale family farms, the demand for incubation is usually small and the hatching volume is not large, so complex or high-capacity equipment is not required. Manual incubators are economical and suitable for farmers with limited budgets, especially those who are interested in the incubation process and are willing to spend time on manual operation. However, if the budget allows, small automatic incubators are also an option worth considering. Automatic incubators can simplify the operation of the incubation process and reduce human errors, especially for family farmers who want to save time and energy.

| Small scale poultry egg incubator capacity(Pcs per set) | Electric heating power(W) | ||||

|---|---|---|---|---|---|

| Chicken egg | Duck egg | Goose egg | Pigeon egg | Quail egg | |

| 88 | 63 | 32 | 112 | 221 | 700 |

| 176 | 128 | 64 | 224 | 442 | 700 |

| 264 | 189 | 96 | 336 | 663 | 700 |

| 352 | 252 | 128 | 448 | 884 | 700 |

| 440 | 315 | 160 | 560 | 1105 | 700 |

| 528 | 378 | 192 | 672 | 1326 | 700 |

| 880 | 630 | 320 | 1120 | 2210 | 1000 |

| 1056 | 756 | 384 | 1344 | 2652 | 1000 |

| 1232 | 882 | 448 | 1568 | 3094 | 1000 |

| 1408 | 1008 | 512 | 1792 | 3536 | 1000 |

| 1584 | 1134 | 576 | 2016 | 3978 | 1000 |

| 1848 | 1323 | 672 | 2352 | 4641 | 1000 |

Medium-sized farms

- Recommended choice: Medium-sized full automatic incubator.

- Reason: Medium-sized farms usually need to incubate a large number of eggs, and manual operation may become cumbersome and prone to errors. Medium-sized automatic egg incubators can improve hatching efficiency and success rate while controlling operating costs. Such equipment is usually equipped with automatic temperature and humidity control functions, which can stabilize hatching conditions and reduce the need for human intervention. For farms that want to control costs while ensuring production efficiency, choosing a medium-sized automatic incubator is a balanced solution.

| Medium scale poultry egg incubator capacity(Pcs per set) | Electric heating power(W) | ||||

|---|---|---|---|---|---|

| Chicken egg | Duck egg | Goose egg | Pigeon egg | Quail egg | |

| 2112 | 1512 | 768 | 2688 | 5304 | 1600 |

| 2376 | 1701 | 864 | 3024 | 5967 | 1600 |

| 2640 | 1890 | 960 | 3360 | 6630 | 1600 |

| 2816 | 2016 | 1024 | 3584 | 7072 | 1600 |

| 3168 | 2258 | 1152 | 4032 | 7956 | 1600 |

| 3520 | 2520 | 1280 | 4480 | 8840 | 1600 |

| 3872 | 2772 | 1408 | 4928 | 9724 | 2000 |

| 4224 | 3024 | 1536 | 5376 | 10608 | 2000 |

| 4576 | 3276 | 1664 | 5824 | 11492 | 2000 |

| 5280 | 3780 | 1920 | 6720 | 13260 | 2000 |

| 6336 | 4536 | 2304 | 8064 | 15912 | 2000 |

| 8448 | 6048 | 3072 | 10752 | 21216 | 3200 |

Large commercial farms

- Recommended choice: High-capacity automatic incubators.

- Reasons: The production scale of large commercial farms determines that their equipment requirements are more stringent and efficient. High-capacity full automatic incubators can not only process a large number of eggs at one time but are also equipped with advanced automated management systems, which can greatly reduce the need for manual operation. Such equipment usually has functions such as remote monitoring and intelligent control, which can ensure that the incubation conditions are always in the best state, thereby greatly improving the hatching success rate. For large commercial farms that pursue high production, low labor costs, and hope to improve their competitiveness through technology, high-capacity automatic incubators are the most suitable choice.

| Large scale poultry egg incubator capacity(Pcs per set) | Electric heating power(W) | ||||

|---|---|---|---|---|---|

| Chicken egg | Duck egg | Goose egg | Pigeon egg | Quail egg | |

| 9856 | 7056 | 3584 | 12544 | 24752 | 3200 |

| 12672 | 9072 | 4608 | 16128 | 31824 | 4800 |

| 14784 | 10548 | 5376 | 18816 | 37128 | 4800 |

| 16896 | 12095 | 6144 | 21504 | 42432 | 6400 |

| 19712 | 14112 | 7186 | 25088 | 49504 | 6400 |

| 22528 | 16128 | 8192 | 28672 | 56576 | 6400 |

Cost-effectiveness analysis

Return on investment

Manual egg incubator: The initial investment cost of a manual egg incubator is low and it is suitable for small family farmers with limited budgets. Due to the simple equipment, farmers can start hatching without investing a lot of money. However, as the incubation scale increases, the economic benefits of manual egg incubators may be limited in the long term. Frequent manual operations increase time costs and easily lead to human errors, which in turn affects the success rate of hatching.

Full automatic incubators: The initial investment cost of full automatic incubators is higher, especially for large-capacity equipment. However, fully automatic egg incubators can significantly improve hatching efficiency and success rates, reducing the need for manual operations. In the long term, automatic egg incubators can bring higher economic benefits to farmers by increasing production and reducing labor costs. For medium-sized farms, investing in an automatic egg incubator can often pay for itself in a shorter period and achieve higher profits.

Operating costs

Manual incubator: The operating costs of manual incubators are mainly concentrated in labor costs. Due to the need for frequent manual adjustments to temperature, humidity, and egg turning, farmers need to invest a lot of time and energy.

Automatic incubator: Although the initial investment in automatic incubators is higher, they have higher efficiency and lower labor requirements in daily operation. Automatic incubators are equipped with automatic temperature control, humidity adjustment and egg-turning functions, which not only reduce the need for human intervention but also can more accurately control the incubation conditions, thereby reducing energy consumption and improving the hatching success rate.

Incubation success rate and benefits

Manual egg incubators: Due to their reliance on manual operation, the hatching success rate of manual egg incubators is often lower than that of automatic egg incubators. Human factors such as operating errors, negligence, or failure to adjust incubation conditions in time will lead to incubation failure.

Full automatic incubator: A full automatic incubator can significantly improve the hatching success rate through precise automatic control. Stable temperature and humidity control, as well as regular automatic egg turning, can ensure the normal development of embryos and reduce the risk of hatching failure. A higher hatching success rate means more healthy chicks, thereby improving breeding efficiency. For large-scale farmers, choosing an automatic egg incubator will not only bring higher production but also ensure the stability and predictability of the production process, thereby achieving long-term economic returns.