What is an Egg Tray Production Line?

The egg tray production line is a collection of equipment consisting of an egg tray machine as the main equipment and a series of auxiliary equipment such as egg tray drying system, pulp system, and packaging equipment. Customers who purchase the egg tray production line can directly start egg tray production without purchasing other equipment separately. The egg tray production line is an efficient and highly automated system for the manufacture of high-quality pulp egg trays for the packaging and transport of eggs.

The Main Equipment of Egg Tray Production Line

The equipment in the egg tray production line can handle the production of large quantities of egg trays and ensure the quality and consistency of the products, so it has been respected and welcomed by many egg tray manufacturers. So, what main equipment does the egg tray production line include?

Pulp equipment: pulper, vibrating screen, water pump, refiner, agitator, etc.

Egg tray forming equipment: egg tray machine, mould, vacuum pump, vacuum tank, air compressor, air compressor tank, high-pressure water pump, etc.

Egg tray drying equipment: hot air blower, dehumidification fan, dehumidification pipe, burner, combustion chamber, conveyor belt, chain, etc.

Egg tray packaging equipment: heat press, stacker, compaction equipment, baler, etc.

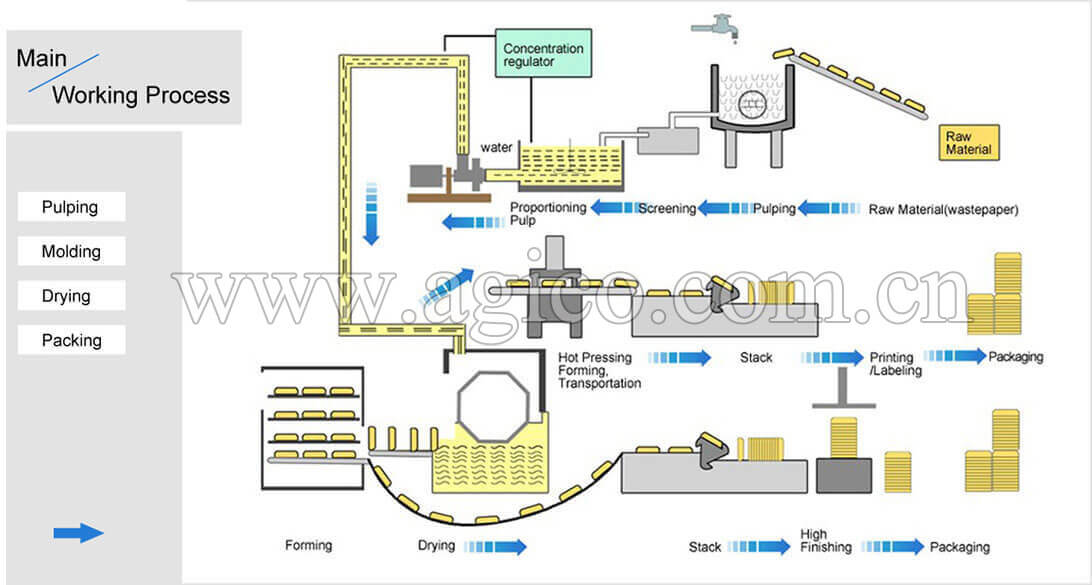

Egg Tray Production Process

Pulping system for paper tray production

Pulping system for paper tray production

Drying equipment for egg tray production line

Packing equipment for egg tray production line

- Raw material preparation: The production of egg trays usually uses waste paper or other fibrous materials. These raw materials are beaten and refined to make pulp.

- Drying and solidifying: The moulded egg trays enter a drying system where they are solidified and moisture is removed through controlled temperature and ventilation.

- Heat-pressing treatment: The dried egg tray enters the heat-pressing system and is treated with high temperature and pressure to make it stronger and more durable.

- Counting and packing: Autoclaved egg trays are automatically counted, stacked and packed for easy storage and shipping.

Egg Tray Production Line or Just an Egg Tray Machine, How to Choose?

When choosing to buy an egg tray machine or an egg tray production line, AGICO, an expert in egg tray technology, suggests that you should comprehensively consider factors such as production requirements, scale, growth plan, automation requirements, and capital budget, weigh the pros and cons, and choose the most suitable solution for you.

Egg tray machine

- Production needs: If your production needs are relatively low, and you only need to produce egg trays on a small scale, purchasing a single egg tray machine may be an economical option. This meets your current needs and is less expensive.

- Money Budget: Considering your money budget is also an important factor. Purchasing a complete set of egg tray production line equipment may require a larger investment while purchasing a single egg tray machine can achieve production within a smaller budget.

1000-1700pcs/h Egg Tray Moulding Machine

2000-2700pcs/h Paper Pulp Egg Tray Making Machine

3000-9000pcs/h Paper Egg Tray Machine

6000-6500pcs/h Egg Tray Manufacturing Machine

Egg tray production line

- Production scale and growth plan: If you plan to expand the production scale to meet greater market demand, or expect to increase the production of other related products in the future, it may be more appropriate to purchase a complete set of egg tray production line equipment. A full set of equipment can provide an integrated production solution, improve production efficiency, and provide greater flexibility for future expansion.

- Automation and efficiency: The complete set of egg tray production line equipment usually has automation functions, which can reduce manpower input and improve production efficiency and stability. If you are pursuing high-efficiency and automated production, it will be a wise choice to purchase an egg tray production line.

AGICO egg tray production line specifications

| Model | Output(p/h) | Mold | Pulping Machine | Egg Tray Machine | Drying Method | |||

|---|---|---|---|---|---|---|---|---|

| Natural Drying | Brick Drying | Single Layer Metal Drying | Multilayer Metal Drying | |||||

| ZMDT3×1-1000 | 1000-1200 | 3×1 | ZDS1 | DT3×1 | √ | √ | ||

| ZMDT4×1-1500 | 1500-1700 | 4×1 | ZDS1 | DT4×1 | √ | √ | √ | √ |

| ZMDT3×4-2000 | 2000-2200 | 3×4 | ZDS1 | DT3×4 | √ | √ | √ | √ |

| ZMDT4×4-2500 | 2500-2700 | 4×4 | ZDS2 | DT4×4 | √ | √ | √ | √ |

| ZMDT3×8-3000 | 3000-3500 | 3×8 | ZDS2 | DT3×8 | √ | √ | √ | |

| ZMDT4×8-4000 | 4000-4500 | 4×8 | ZDS4 | DT4×8 | √ | √ | √ | |

| ZMDT5×8-5000 | 5000-5500 | 5×8 | ZDS4 | DT5×8 | √ | √ | √ | |

| ZMDT5×12-6000 | 6000-6500 | 5×12 | ZDS6 | DT5×12 | √ | √ | √ | |

What Products can the Egg Tray Production Line Produce?

The egg tray production line can produce pulp egg trays of various specifications and pulp mold products of various products.

Egg Carton

Duck Egg Tray

Quail Egg Carton

Friut Tray

| Category | Chicken egg tray | Egg carton | Duck egg tray | Goose egg tray | Quail egg tray | Piegon egg tray |

|---|---|---|---|---|---|---|

| Specifications | 20, 24 and 30 holes | 6, 12, 16, 18, and 24 packs | Based on customer needs | Based on customer needs | Based on customer needs | Based on customer needs |