Hatching goose eggs is a complex and delicate task. Due to their unique size and thick eggshells, precise temperature and humidity control in the incubation equipment is required. To help farmers meet this challenge, AGICO has specially developed this goose incubator. Whether in small farms or large and medium-sized farms, the newly designed goose egg incubator can provide the most ideal hatching environment for your goose eggs and pursue a higher hatching rate.

Special Challenges of Goose Egg Hatching

Hatching problems with large eggs

Goose eggs are known for their large size and sturdy structure, and they require longer time and more complicated operations to incubate than small poultry egg incubators such as chicken egg incubators and quail egg incubators. Goose eggs have thicker shells and a larger surface area, which makes it more difficult for heat and moisture to transfer during incubation. Conventional incubation equipment is often designed for smaller eggs and cannot effectively handle the unique needs of goose eggs.

Thick eggshell air permeability and temperature and humidity management

The thick shell structure of goose eggs not only increases the difficulty of heat conduction but also affects the gas exchange inside and outside the egg. During incubation, the embryo requires a steady supply of oxygen and removal of carbon dioxide, and a thick eggshell can restrict these critical processes.

Goose Incubator Features Designed Specifically for Goose Egg

Incubation Heating system designed specifically for large poultry eggs

Accurate temperature control is critical to the successful hatching of geese eggs. Goose eggs are enormous, therefore in order to guarantee the embryo develops healthily during the incubation phase, all areas of the egg must be heated uniformly. Traditional commercial poultry incubators can heat eggs unevenly, causing one part of the egg to overheat or another part to underheat. To address this problem, this goose incubator uses a heating system designed specifically for large eggs. Through multi-point temperature control technology and optimized thermal cycle design, the incubator can maintain stable and uniform temperature distribution throughout the incubation chamber. Regardless of the location of the egg, the goose incubator ensures that every part of the egg is within the optimal temperature range, significantly increasing hatching success rates.

Adjustable humidity system

Controlling the humidity is also essential for the successful incubation of geese eggs. The humidity needs for geese eggs vary depending on the stage of incubation because of their thick shell structure, which facilitates the evaporation of the water inside. During the early stages of incubation, moderate humidity can protect the embryo's development and prevent the eggs from losing too much water. Increased humidity in the later stages of incubation, especially during the shell-pecking stage, may cause the eggshell to deteriorate and make it easier for the goslings to get free.

This goose incubator designed and produced by AGICO is equipped with a sophisticated adjustable humidity system that can automatically adjust the internal humidity level according to the different needs of the incubation stage. In the early stages, the system maintains a low humidity to prevent excessive evaporation; in the last few days of incubation, the humidity will be gradually increased to 70%-75% to ensure that the embryos can complete their development and hatch successfully. Through this intelligent humidity regulation function, the goose egg incubator can provide an ideal growth environment for each goose egg, maximizing the hatching rate and the health of the goslings.

Optimized design of automatic egg turning function

Hydronic system

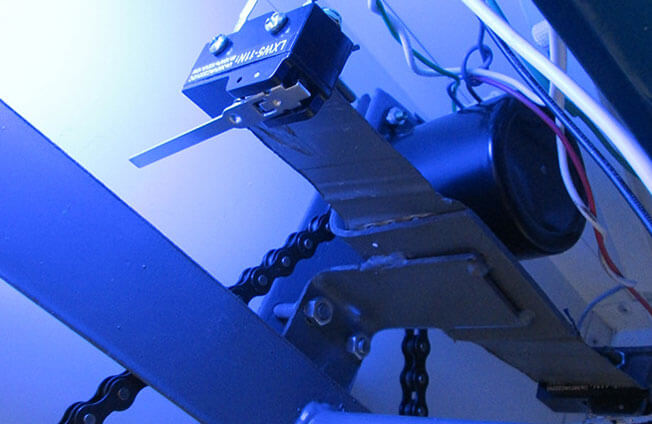

Mute motor evenly turns egg

High precision temperature and humidity sensor

The size and weight of goose eggs make turning the eggs particularly critical, as it not only helps the embryos heat evenly but also prevents them from sticking to the shell, thus ensuring their normal development. However, goose eggs are larger and heavier than other eggs, and traditional egg-turning mechanisms may not be sufficient to handle these characteristics, which can easily lead to incomplete turning or over-frequent turning, which will affect the hatching effect.

With an optimal automatic egg-turning mechanism, this goose incubator caters to the unique requirements of geese eggs. The egg incubator can guarantee that the geese are automatically rotated every two hours at a about 45-degree angle thanks to its improved egg turner and accurate egg turning angle control. This design successfully keeps the embryo from adhering to the shell while also imitating the mother geese's egg-turning activity during normal incubation. Simultaneously, the incubator's structural layout guarantees stability while the eggs are being turned, and even with a huge egg capacity, it can maintain a smooth turning motion to prevent the embryo from being unduly stressed.

Smart incubation program

Goose egg incubation is a delicate and intricate process that involves varying temperature, humidity, and frequency of egg turning at different stages. With a built-in intelligent incubation program designed especially for geese eggs, this incubator can automatically modify a number of important parameters based on how well the eggs are incubating. In addition to controlling temperature and humidity, the clever program dynamically modifies the frequency of egg turning to guarantee that the settings at each stage precisely correspond with the requirements of the embryo's development.

The goose incubator keeps the temperature steady and the humidity low throughout the first several days of incubation to guarantee the embryo's good development. The frequency of egg turning will be changed to match the embryo's growth pace as soon as the incubation reaches the middle stage. The goose incubator will automatically lower the frequency of flipping the eggs and raise the humidity during the last stage of pecking to create the ideal conditions for hatching. This fully automatic hatching management makes handling every aspect of the hatching process easy and not only significantly streamlines the operation procedure but also substantially increases the hatching success rate.

Goose Egg Incubators for Sale

64 goose egg incubators for sale

768 goose egg incubators for sale

1152 goose egg incubators for sale

| Scale | Small Scale | Medium Scale | Large Scale | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity(Pcs per set) | 32 | 64 | 96 | 128 | 160 | 192 | 320 | 384 | 448 | 512 | 576 | 672 | 768 | 864 | 960 | 1024 | 1152 | 1280 | 1408 | 1536 | 1664 | 1920 | 2304 | 3072 | 3584 | 4608 | 5376 | 6144 | 7186 | 8192 |

| Electric heating power(W) | 700 | 700 | 700 | 700 | 700 | 700 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | 2000 | 2000 | 2000 | 2000 | 2000 | 3200 | 3200 | 4800 | 4800 | 6400 | 6400 | 6400 |