In the farming industry, selecting the right commercial poultry incubator is crucial to successful breeding, especially for those looking to efficiently hatch quail eggs in incubator. Due to their small size and unique incubation requirements, quail eggs need a commercial quail egg incubator with precise temperature and humidity control to ensure each batch hatches under optimal conditions. Our quail egg incubators are specifically designed to meet these demands, optimizing the hatching process while maximizing space utilization and resource efficiency through high-density incubation and energy-saving features. Whether you're a small-scale farmer or a large commercial operation, our incubators will help you increase productivity, seize market opportunities, and achieve breeding success.

Commercial Quail Egg Incubator Come with Features Specifically Designed for Hatching Quail Eggs

Hatching quail eggs in incubator requires specific conditions, and quail egg incubators are meticulously designed to meet these needs. Unlike hen egg incubators or duck egg incubators, quail egg incubators are tailored to the smaller size and shorter incubation period of quail eggs. Therefore, precise control of temperature and humidity is crucial during the incubation process. Quail egg incubators maintain a temperature of around 37.5°C and feature an automatic humidity regulation system to ensure the hatching environment is always optimal for embryo development. This precise control not only improves the hatching success rate but also effectively reduces human error.

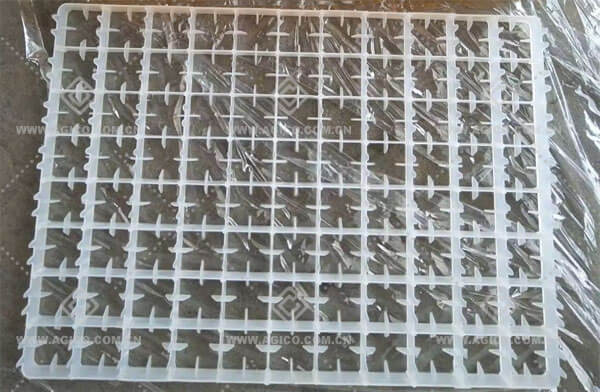

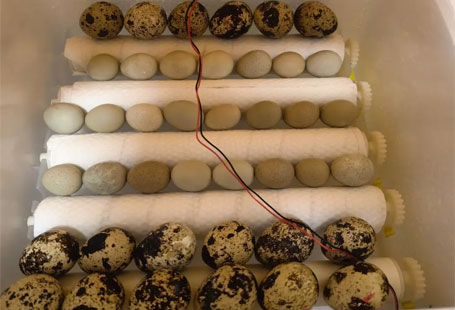

Additionally, quail eggs are small and fragile, making them difficult to handle with traditional incubator designs. Commercial quail egg incubators have been optimized to address this challenge. The specially designed egg trays securely hold the quail eggs, preventing them from moving or being damaged during incubation. Meanwhile, the ventilation system is specially adjusted to ensure even airflow, avoiding the risk of overheating or cooling that could occur due to the small size of the eggs. These design features make the incubator not only ideal for quail eggs but also suitable for other small poultry eggs, thereby expanding its range of applications.

Egg tray for quail egg incubator

Hatching basket for quail chicks

With these specialized features and designs, quail egg incubators offer an efficient and reliable solution, ensuring that every quail egg hatches under optimal conditions. This incubator, specifically tailored for quail eggs, significantly enhances hatching efficiency, making it the ideal choice for both small-scale farmers and professional breeding operations.

Quail Egg Incubator for Sale

442 commercial quail egg incubator

2210 commercial quail egg incubator

5304 commercial quail egg incubator

15912 commercial quail egg incubator

| Scale | Small Scale | Medium Scale | Large Scale | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity(Pcs per set) | 221 | 442 | 663 | 884 | 1105 | 1326 | 2210 | 2652 | 3094 | 3536 | 3978 | 4641 | 5304 | 5967 | 6630 | 7072 | 7956 | 8840 | 9724 | 10608 | 11492 | 13260 | 15912 | 21216 | 24752 | 31824 | 37128 | 42432 | 49504 | 56576 |

| Electric heating power(W) | 700 | 700 | 700 | 700 | 700 | 700 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1600 | 1600 | 1600 | 1600 | 1600 | 1600 | 2000 | 2000 | 2000 | 2000 | 2000 | 3200 | 3200 | 4800 | 4800 | 6400 | 6400 | 6400 |

High-Density Incubation and Space Optimization

Greater yield:

Due to the small size of quail eggs, commercial quail egg incubators can manage a higher number of eggs within a confined space, enabling high-density incubation. Compared to incubators designed for chicken or duck eggs, quail egg incubators can fit more egg trays in the same space, significantly increasing the output per batch. This capability for high-density incubation is especially attractive to breeders aiming to maximize production efficiency.

Optimized space utilization:

Quail egg incubators excel not only in capacity but also in space efficiency. In small to medium-sized farms, where space is often a valuable resource, these incubators are designed to maximize every inch of space without compromising the quality of incubation. This means higher yields and smaller physical footprints, making the equipment easier to place and operate in confined environments.

Lower operating costs:

Additionally, the optimized design contributes to lower operating costs. Higher egg density allows for more eggs to be processed in the same amount of time, shortening production cycles and increasing output rates. For medium-sized farms, this efficient use of space in quail egg incubators not only meets daily incubation needs but also proves invaluable during peak production periods.

Incubating Different Quail Breeds

The diversity in quail farming makes the adaptability of an incubator crucial. When incubating different quail breeds, slight variations in their incubation requirements necessitate an incubator that is flexible and capable of making precise adjustments.

Performance and optimization for different quail breeds

An incubator's ability to handle various quail breeds with flexibility is a key feature that appeals to diversified farmers. Whether it's the common Japanese quail, the smaller American quail, or other unique breeds, the incubator can be adjusted to meet the specific incubation needs of each breed, ensuring optimal conditions. These incubators are precisely designed to automatically adjust temperature, humidity, and ventilation to accommodate the unique embryonic development characteristics of each breed, thereby increasing the hatching success rate.

Adjusting incubator settings to accommodate different quail breeds

For various quail breeds, the commercial quail egg incubator can optimize the hatching process by adjusting incubation parameters either through presets or manual settings. For instance, Japanese quail typically requires higher incubation temperatures, while other breeds may need longer incubation times or different humidity controls. The incubator's intelligent control system allows farmers to customize the incubation program for each breed, ensuring that every batch of quail eggs develops in the most suitable environment. By adjusting the incubator settings, farmers can effectively manage the challenges of multi-breed hatching while maintaining efficient production and consistent output.

Maintenance and After-Sales Service

AGICO commercial quail incubator workshop

AGICO commercial quail incubator workshop AGICO commercial quail incubator workshop

AGICO commercial quail incubator workshop AGICO commercial quail incubator workshop

AGICO commercial quail incubator workshopWhen choosing a commercial quail egg incubator, ease of maintenance and reliable after-sales service are crucial factors for many farmers. Efficient maintenance and high-quality after-sales support not only extend the lifespan of the equipment but also reduce the long-term operating costs of the farm, ensuring that the equipment continues to operate efficiently.

Ease of maintenance

AGICO’s quail egg incubators are designed with careful consideration to ensure that routine maintenance is simple and quick. The key components of the equipment, such as the heating system, humidity controller, and fan, are easy to remove and clean, minimizing downtime. Farmers can maintain the incubator's stable performance through regular, simple inspections and maintenance. To assist customers in maintaining the equipment, AGICO provides detailed operation manuals and maintenance guides, instructing users on how to properly care for the incubator and extend its lifespan.

After-sales service and support

In addition, we offer online support and a 24-hour customer service hotline, allowing customers to quickly receive solutions when issues arise. These service options effectively reduce the inconvenience caused by equipment malfunctions, enhancing the customer experience and satisfaction.