The 1000 egg incubator is a medium-scale, fully automatic hatching device developed and designed by AGICO, following the 100 egg incubator and 500 egg incubator. The biggest feature of the 1000 egg incubator is that its hatching capacity has been greatly improved. It can hatch 1000 eggs at the same time, which makes it more suitable for medium and large-scale farms to carry out batch egg hatching. The price of the 1000 egg incubator is moderate, the product quality is reliable, the operation process is simple, and it can effectively improve the hatching success rate of poultry eggs.

Product Specifications of 1000 Egg Incubator

1000 egg incubator for chicken egg

| Types of poultry eggs | Hatching quantity |

|---|---|

| Chicken egg | 1056 |

| Types of poultry eggs | Hatching quantity |

|---|---|

| Chicken egg | 1232 |

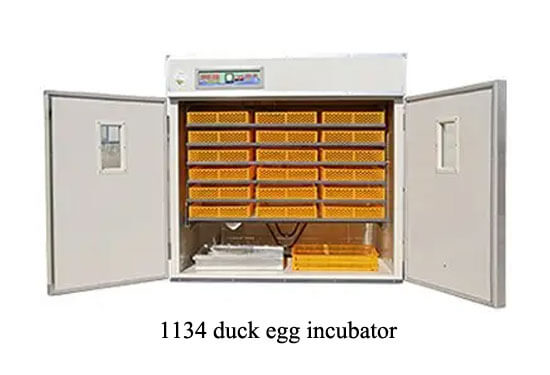

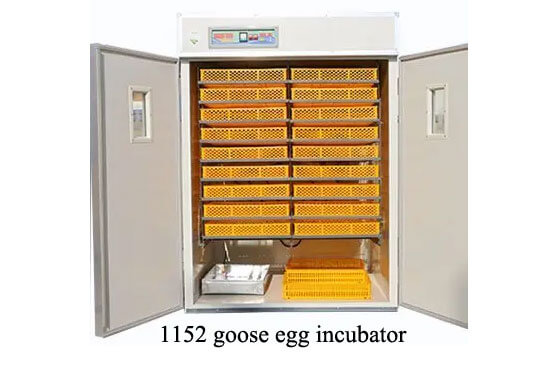

1000 egg incubator for duck egg and goose egg

| Types of poultry eggs | Hatching quantity |

|---|---|

| Duck egg | 1008 |

| Duck egg | 1134 |

| Types of poultry eggs | Hatching quantity |

|---|---|

| Goose egg | 1024 |

| Goose egg | 1152 |

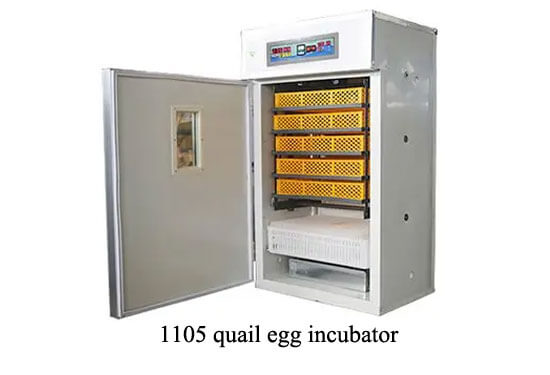

1000 egg incubator for pigeon egg and quail egg

| Types of poultry eggs | Hatching quantity |

|---|---|

| Pigeon egg | 1120 |

| Types of poultry eggs | Hatching quantity |

|---|---|

| Quail egg | 1105 |

1000 Egg Incubator for Sale

The following are the core features of the 1000 egg incubator, providing users with a reliable hatching experience:

Incubation capacity

The 1000 egg incubator can hold 1000 eggs and is suitable for medium-sized and large farms and commercial farms. The incubator has a reasonable internal design, which can provide sufficient space and suitable air circulation so that each egg can enjoy good incubation conditions.

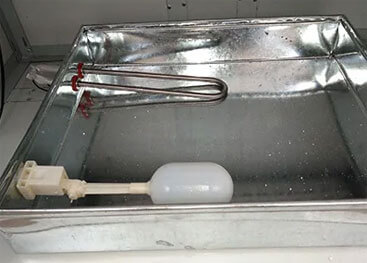

Accuracy of temperature and humidity control

The 1000 egg incubator is equipped with an advanced temperature and humidity control system that can monitor and adjust the temperature and humidity in the incubation room in real-time, ensuring that the entire incubation process is carried out in a suitable environment to avoid overheating or overcooling that affects embryo development.

Energy-saving effect

The 1000 egg incubator adopts an energy-saving design, which reduces energy consumption while ensuring efficient operation of the equipment and is suitable for long-term stable operation. The use of high-efficiency motors and thermal insulation materials helps save operating costs, especially suitable for farms that require continuous incubation.

Material durability

The use of high-quality metal and heat-resistant materials ensures that the 1000 egg incubator can maintain structural stability and is not easily damaged even in high temperature environments. Both the outer shell and internal structure are designed to be anti-corrosion and rust-proof, which helps to extend the service life of the equipment.

Automatic egg turning function

The 1000 egg incubator is equipped with a fully automatic egg turning system, which automatically turns the egg tray according to the set time interval, avoiding the inconvenience caused by manual operation and improving the hatching efficiency and success rate. This function can also prevent the embryo from sticking to the shell and ensure the healthy development of the embryo.

Air circulation design

A reasonable air circulation system is used inside to ensure that fresh air is evenly distributed, promote heat conduction, and avoid local overheating. The air circulation system is adjustable to adapt to different environmental temperature requirements to ensure that every egg is in a good incubation state.

What is the 1000 Egg Hatching Machine Price?

When purchasing incubation equipment, the price of the incubator is a key factor to consider. The AGICO-designed and manufactured 1000 egg incubator price between $200 and $500. This is the ex-factory price for the unit itself and does not include shipping or additional fees. The 1000 egg incubator price will fluctuate according to some factors. The specific influencing factors include the following:

-

Types of eggs to be incubated

In the case of incubating 1,000 eggs, due to the different sizes and spaces required for the incubation of different types of eggs, the size of the 1,000 quail incubator is much smaller than that of the 1,000 goose egg incubator, so the material consumption will be relatively less, so the prices of these two different types of egg incubators will naturally be different. Under the premise of the same egg number of incubations, the smaller the size of the eggs, the smaller the design size of the incubator will be, and the price will be relatively lower. -

Special customization needs

Some customers may customize designs based on their own needs, such as specific eggs (such as peacock eggs, parrot eggs, snake eggs, etc.), or require incubators of special specifications. Such customized incubators will increase some design and production costs, so the overall price will also be affected. -

Additional functions

The price of a 1000 egg incubator will also vary with the addition of additional functions. For example, an incubator with higher-precision temperature and humidity control, a smarter digital control panel, and a dual air circulation system are usually more expensive and suitable for users who have more stringent requirements for the incubation environment.

1000 Egg Incubator has Lower Hatching Cost Per Egg

Compared with smaller capacity incubators, such as 100 egg incubator, 200 egg incubator, and 500 egg incubator, this 1000 egg incubator has lower per egg hatching cost. Small-capacity incubators have limited hatching capacity and are suitable for small-scale or family farming. 1000 egg incubators are more suitable for medium and large-scale farms, reducing operating costs through large-scale hatching. For users who need efficient output, 1000 egg incubators show higher cost-effectiveness in large-scale production.